导图社区 机器人Industrial Robot

- 375

- 20

- 6

- 举报

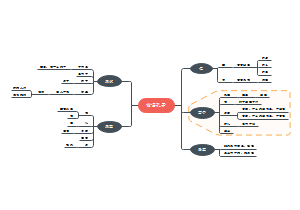

机器人Industrial Robot

想了解关于机器人知识的可以看看 还是要注重实际的生产,理论仅仅是理论

编辑于2020-04-27 19:51:42- 机器人

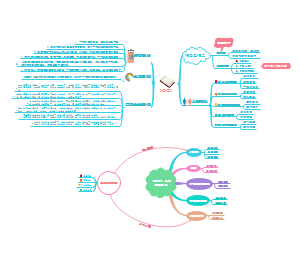

- 反脆弱,随机漫步的傻瓜

你想从随机性中发现财富的密码吗?你想从反脆弱中找到投资的机会和成长的法则吗? 人应该做随机性的主宰,而不是被随机性主宰; 脆弱的反义词是反脆弱,投资的两头策略非常值得我们学习

- 黑天鹅,灰犀牛

要准确的认识到黑天鹅和灰犀牛的定义和所描述的情况,比如为什么当代黑天鹅的事情越来越多?人们为什么即使知道灰犀牛事件也会选择一种“集体无意识”的态度去忽略它。两本书是同一个作者写的,在思维观点上对于刚接触的人会很耳目一新

- 文明的冲突与世界秩序的重建 硬球政治 权力的转移

文明的建立和现代文明的描述,现代化并不产生普世文明;文明冲突下全球的政治格局是什么样的;信息就是权力,从一个国家到一个小公司,谁掌握了信息并能正确的利用信息,谁就能抓住权力的鞭子,身为个体要有一定的信息分辨能力;硬球政治的含义其实就是毛主席说的团结大多数人,把自己的朋友搞的多多的,敌人的朋友搞的少少的。

机器人Industrial Robot

社区模板帮助中心,点此进入>>

- 反脆弱,随机漫步的傻瓜

你想从随机性中发现财富的密码吗?你想从反脆弱中找到投资的机会和成长的法则吗? 人应该做随机性的主宰,而不是被随机性主宰; 脆弱的反义词是反脆弱,投资的两头策略非常值得我们学习

- 黑天鹅,灰犀牛

要准确的认识到黑天鹅和灰犀牛的定义和所描述的情况,比如为什么当代黑天鹅的事情越来越多?人们为什么即使知道灰犀牛事件也会选择一种“集体无意识”的态度去忽略它。两本书是同一个作者写的,在思维观点上对于刚接触的人会很耳目一新

- 文明的冲突与世界秩序的重建 硬球政治 权力的转移

文明的建立和现代文明的描述,现代化并不产生普世文明;文明冲突下全球的政治格局是什么样的;信息就是权力,从一个国家到一个小公司,谁掌握了信息并能正确的利用信息,谁就能抓住权力的鞭子,身为个体要有一定的信息分辨能力;硬球政治的含义其实就是毛主席说的团结大多数人,把自己的朋友搞的多多的,敌人的朋友搞的少少的。

- 相似推荐

- 大纲

Industrial Robot

Bright and challenging prospects for industrial robot installations

Energy-efficiency and using new materials require continuous retooling of production

Rapid production and delivery of customised products at competitive prices are main incentives to automate production

Automation enables manufacturers to keep or to relocate production in developed economies without sacrificing cost efficiency

Localization and regionalization of production will increase to respond swiftly to customer demands in local markets, shorten production lead time and reduce logistical and political risks

The digitalization of production (Industry 4.0), linking the real-life factory with virtual reality, will continue to play an increasingly important role in global manufacturing

The range of industrial robots continues to expand – from traditional caged robots capable of handling all payloads, fast and precise, to newer collaborative robots that can work safely alongside humans, and robots that can be fully integrated into workbenches

Robots work around the clock with a consistent standard of quality and perform an increasing range of so-called 3D (dull, dirty and dangerous) tasks, improving workers’ health, safety and job satisfaction. Robot adoption can enable workers to move on to higher-skilled tasks such as production planning and supervision

Ease of programming - ready to use applications are getting more popular with the customers.

Ease of integration /plug and play - it is becoming easier to link robots into manufacturing production systems, with wide-ranging benefits for process optimization

Self-optimization: robots can increasingly adjust their parameters to adapt to realtime conditions, reducing the risk of defects and enabling manufacturers to improve process quality

Cloud Robotics – Storing data from multiple robots performing the same process in the cloud provides a storage of data on which to apply machine learning to optimise robots’ performance

Global competition requires continuous modernization of production facilities

Growing consumer markets require expansion of production capacities

Continued, strong demand from the automotive industry – investments in eco-friendly driving systems

Increasing demand from the electrical/electronics industry

Increasing demand from the metal and machinery industry, the rubber and plastics industry, and the food and beverage industry

Three Laws of Robotics

A robot may not injure a human being, or, through inaction, allow a human being to come to harm

A robot must obey the orders given it by human beings except where such orders would conflict with the First Law

A robot must protect its own existence as long as such protection does not conflict with the First or Second Law

Three Laws of Robotics Applications

Robots must continue to replace people on dangerous jobs. (This benefits all.)

Robots must continue to replace people on jobs people do not want to do. (This also benefits all.)

Robots should replace people on jobs robots do more economically. (This will initially disadvantage many, but inevitably will benefit all as in the first and second laws.)

Industrial robot as defined by ISO 8373:2012:

An automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications

Characterization

Automated

Repetitive actions

Intelligent artificial

Programmable

designed so that the programmed motions or auxiliary functions can be changed without physical alteration

Capable of movement on three axises or more

Mutli purpose

capable of being adapted to a different application with physical alteration

Physical alteration

alteration of the mechanical system (the mechanical system does not include storage media, ROMs, etc.)

Role of Industrial Robots in Lean Manufacturing System

Somethings need consider

Flexibility required in the process

Budget available for the entire system

Human machine interface requirements

Allowable scrap rate

Life cycle of manufactured product to ensure acceptable ROI

Line automation requirements (% Automation Vs Manual)

Line production rate requirement

Space availability for robotic operations

Equipment reliability and downtime statistics

Flexibility of process desired

Product handling requirements

Cycle time requirements by station or operation

Human machine interface requirements

Number of product variants

Product handling requirements

Maintenance requirements

Conveyor and other transportation requirements

Repair time of equipment

Safety standards and ergonomics guidelines

Application

There is no wait time for operators. A material handling robot can be set up to multi-task, performing additional processing operations between operations

Robots have negligible downtime. Robots deliver a limited production loss compared to manual operations which tend to be error prone and inconsistent in terms of production rate, shifts, work breaks, etc

Robots are less expensive to operate, compared to human labor – especially when overtime is required. Robots’ return on investment can be quickly realized when there is high demand for the manufactured product

Robots are capable of highly accurate, highly repeatable tasks, which results in lowered scrap parts once the robot tasks are optimize

ROBOTS AND CYCLE TIME

Lack of part inventory for robots causing delays in production

Unsafe work conditions causing slow human operation in situations where robots and humans work in a cooperative environment

Poor equipment design resulting in wasted repair efforts

Bottlenecked stations causing part blocking or starvation at other stations

Individual robots over cycle causing entire station to be over-cycle

Wait times on other equipment causing robots to go over-cycle

Poor processing resulting in work overload on robots, operators or machines

Poor human machine interface causing delays in manufacturing

Poor software and controls engineering resulting in inefficient I/O and communication between equipment

Typical applications

Material handling

The manipulator must be able to lift the parts safely

The robot must have the reach needed

The robot must have cylindrical coordinate type.

The robot’s controller must have a large enough memory to store all the programmed points so that the robot can move from one location to another

The robot must have the speed necessary for meeting the transfer cycle of the operation

category

Part replacement

Pick and place for printed circuit boards

Pneumatically powered robots are often utilized

Palletizing

stack parts one on top of the other

A press working operation, where the robot feeds sheet blanks into the press, but the finished parts drop out of the press by gravity.

Bin picking, die casting and plastic moulding

Machine operation

Machine loading or unloading

Stacking and insertion operations

Processing operation

Grinding

Mining

Spot welding

Continuous arc welding

Spray painting

Metal cutting and deburring operations

Various machining operations like drilling, grinding, laser and waterjet cutting and riveting

Rotating and spindle operations

Adhesives and sealant dispensing

Assembly

Batch assembly

As many as one million products might be assembled. The assembly operation has long production runs

Low-volume

In this a sample run of ten thousand or less products might be made. The assembly robot cell should be a modular cell.

Product inspection

Testing

Other applications

Medical

Routine examinations

Surgical procedures

Mining

Space

Underwater

Involves prospecting for minerals on the floor of the ocean

Salvaging of sunken vessels, repair the ship either at sea or in dry dock

Mobile firefighters to be used by air force and navy

Surveillance and Guard duty

military

power generating plants, oil refineries and other civilian facilities that are potential targets of terrorist groups

Requirements

High endurance

High speed

Control resolution

the user might ask for a position such as 456.4mm, and the system can only move to the nearest millimetre, 456mm, this is the accuracy error of 0.4mm

Accuracy

How close does the robot get to the desired point

This measures the distance between the specified position, and the actual position of the robot end effector

Accuracy is more important when performing off-line programming, because absolute coordinates are used

Repeatability

How close will the robot be to the same position as the same move made before

A measure of the error or variability when repeatedly reaching for a single position.

This is the result of random errors only

Repeatability is often smaller than accuracy

Defining parameters

Number of axes

two axes are required to reach any point in a plane

three axes are required to reach any point in space

Degrees of freedom

this is usually the same as the number of axes

Working envelope

the region of space a robot can reach

Kinematics

the actual arrangement of rigid members and joints in the robot, which determines the robot's possible motions

Carrying capacity or payload

how much weight a robot can lift

Speed

How fast the robot can position the end of its arm

Acceleration

how quickly an axis can accelerate

Accuracy

how closely a robot can reach a commanded position

Repeatability

how well the robot will return to a programmed position

ISO 9283 sets out a method whereby both accuracy and repeatability can be measured

Motion control

simple pick-and-place assembly, the robot need merely return repeatably to a limited number of pre-taught positions

For sophisticated applications, welding and finishing (spray painting), motion must be continuously controlled to follow a path in space, with controlled orientation and velocity

Power source

electric motors

faster

hydraulic actuators

stronger and advantageous in applications such as spray painting, where a spark could set off an explosion

Drive

some robots connect electric motors to the joints via gears

harmonic drive

joint directly

Compliance

his is a measure of the amount in angle or distance that a robot axis will move when a force is applied to it

A selective taxonomy of robotics technology

Fixed and caged industrial robots

Designed to operate within physical barriers (includes Articulated arm, SCARA, Cylindrical and Cartesian)

Common tasks

Assembly

Welding

Riveting

Drilling

Fastening

Die casting

Picking/packaging/sorting

Painting/coating

Typical domain

Industrial manufacturing plants and factories

Established industry adopters

Industrial products manufacturing

Retail and consumer

Food and beverage

Electronics

Pharmaceutical

New and future industry adopters

Oil and Gas, pipeline distribution

Construction

All industries adopting robotic additive (3D printing) manufacturing

Collaborative robots

Designed to work side-by-side with humans

category

Collaborative stationary robots

Quickly programmable to augment/supplant manual tasks with humans at a stationary site

Common tasks

Materials handling

In-plant transportation

Product and asset inspection

Assembly

Robotic 3D printing

Picking/packing/sorting

Point-of-sale assembly

Collaborative Autonomous Mobile Robots (AMRs)

(designed to work closely with humans) and automated guided vehicles (AGVs)

Common tasks

Materials handling

In-plant transportation

Automated palletizing

Product/shelf scanning (in warehouse and retail environments)

Brick-laying

Typical domain

Industrial manufacturing

plants/factories

Warehouses

Distribution centers

Pipe networks

Drilling operations

Construction sites

Established industry adopters

Industrial products

manufacturing

Retail (warehouses)

Medicine (assisted surgery)

Semi-conductor

Electronics

Oil and gas industry

Healthcare

Law enforcement

Agriculture

Online retailers

Retail and consumer

New and future industry adopters

Service industries (e.g., hotels, hospitals, restaurants, retailers)

Retail (product scanning and assembly)

All industries adopting robotic additive (3D printing) manufacturing

Construction

Unmanned Aerial Vehicles (UAVs) for surveillance

Low payload industrial aerial drones (under 15lb)

Common tasks

Asset management

Asset inspection (e.g., power plants, wind turbines)

Product/part scanning capability

Autonomous data mapping

Contaminant detection

Inventory tracking/management (RFID-reading)

Aircraft inspection

Construction site illustration

Typical domain

Locales of large-area environmental surveillance (mines, forests, oil rigs, pipe-lines, construction sites, farms, etc.)

Warehouse/fulfillment centers

Airports

Energy assets (oil rigs, wind turbines, power plants)

Established industry adopters

Aerospace

Construction (illustration of sites) Real estate

Oil &Gas

New and future industry adopters

Agriculture (e.g., crops surveillance)

Power utilities (plant, transmission/distribution network inspection)

Mining

Industrial products manufacturing

Unmanned Aerial Vehicles for transport

High payload capacity 15lb+ (Note: 55 lb-payload is highest permitted by FAA, as or August 2016, for commercial delivery applications)

Common tasks

Retrieval and delivery of parts/packages

Typical domain

Private plants and premises

All other airspace permitting UAV use

Established industry adopters

Military

Construction

Emergency medical supplies/food delivery

New and future industry adopters

All industries requiring delivery of low pay-load items

Last-mile delivery of parts or end-user product

In-plant/warehouse inventory management and materials handling

Low payload tasks now carried out by airplanes/helicopters (e.g., spraying crops)

Robotic Exoskeletons

Wearable robotics systems designed to augment human physical performance

Common tasks

Assists manual human labor (e.g., lifting, gripping, carrying)

Typical domain

Manufacturing assembly lines

Warehouses

Established industry adopters

Industrial manufacturing (especially auto sector)

Retail & Consumer (in warehousing operations)

New and future industry adopters

All other industries requiring heavy manual labor, especially in the handling of materials)

Robot programming and interfaces

Software

positional data

procedure

Positional commands

The robot can be directed to the required position using a GUI or text based commands in which the required X-Y-Z position may be specified and edited

Teach pendant

Robot positions can be taught via a teach pendant

Three deadman switch

Lead-by-the-nose

Programming

It is a path in space to be followed by the manipulator, combined with peripheral actions that support the work cycle

To programme a robot , specific commands are entered into the robot’s controller memory and this action may be performed in a number of ways

For limited sequence robots ,programming occurs when limit switches and mechanical stops are set to control the endpoints of its motions

A sequencing device controls the occurrence of the motions, which in turn controls the movement of the joints that completes the motion cycle

For industrial robots with digital computers as controllers three programming methods can be distinguished

Lead-through programming

Task is ‘taught’ to the robot by manually moving the manipulator through the required motion cycle and simultaneously entering the programme into the controller memory for playback.

powered lead-through

manual lead through

Computer-like robot programming languages

Off-line programming

Robot simulation

How to tech robots

manually guiding the robot to the positions of interest, or even along the desired paths or trajectories if human accuracy is enough

having simple ways to make use of CAD data whenever available

using different complementary modalities (paths of communication between the human and the robot), such as speech and gestures

choreographing the task movements, for instance loops and conditions, without requiring extensive programming competencies

means of describing acceptable variation, e.g., as expected or normal deviations from the nominal path

specification of how external sensing should be used for new types of motions or for handling unknown variations

Stages of system integration

Physical

Selecting equipment based on dimensioning for mechanical size, load, and stress

Mechanical interfacing (locations, adapter plates, etc.)

Physical Electrical power supply (voltages and currents for robots, effectors, feeders, etc.)

Connections for analog signals (shielding, scaling, currents, binary levels, etc.)

Communication

Interconnections for single-bit digital I/O

Communication Byte-wise data communication, including latencies and bit rates

Transfer of byte sequences

Configuration

Configuration of messages between interacting devices

Configuration Establishment of services

Tuning for performance and resource utilization

Application

Definition of application-lever functions/services

Task

Application programming, using the application-level services

Long term challenge

Human-friendly task specification, including intuitive ways of expressing permitted/normal/expected variations

Efficient mobile manipulation. Successful implementations and systems are available for both mobility and for manipulation, but accomplished in different systems and using different types of (typically incompatible) platforms

Low-cost components including low-cost actuation. Actuation of high-performance robots represent about a third of the overall robot cost, and improved modularity often results in a higher total hardware cost (due to less opportunities for mechatronic optimization)

Composition of subsystems. Inmost successful fields of engineering, the principle of superposition holds, meaning that problems can be divided into subproblems and that the solutions can then be superimposed (added/combined) onto each other such that the total solution comprises a solution to the overall problem.

Embodiment of engineering and research results. Use or deployment of new technical solutions today still starts from scratch, including analysis, understanding, implementation, testing, and so on

Open dependable systems. Systems need to be open to permit extensions by third parties, since there is no way for system providers to foresee all upcoming needs in a variety of new application areas

Sustainable manufacturing. Manufacturing is about transformation of resources into products, and productivity (low cost and high performance) is a must

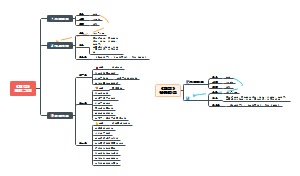

Structure and anatomy of industrial robot

Joints and links <U:\Private\Industrail Robot\joints and links.png>

Linear joint (type L joint)

Orthogonal joint (type U joint)

Rotational joint (type R joint)

Twisting joint (type T joint)

Revolving joint (type V-joint, V from the “v” in revolving)

Five common body-and-arm configurations

Polar configuration

Cylindrical configuration

axes form a cylindrical coordinate system

Cartesian co-ordinate robot

robot whose arm has three prismatic joints and whose axes are coincident with a cartesian coordinate system

Jointed-arm robot

SCARA

has two parallel rotary joints to provide compliance in a plane

Articulated

arm has at least three rotary joints

Parallel

arms have concurrent prismatic or rotary joints

three types of drive systems

Hydraulic drive

It gives a robot great speed and strength. They provide high speed and strength, hence they are adopted for large industrial robots.

This type of drives are preferred in environments in which the use of electric drive robots may cause fire hazards

Example: In spray painting

Disadvantages

Occupy more floor space for ancillary equipment in addition to that required by the robot.

There are housekeeping problems such as leaks

Electric drive

This provides a robot with less speed and strength. Electric drive systems are adopted for smaller robots

Robots supported by electric drive systems are more accurate, exhibit better repeatability and are cleaner to use

Electrically driven robots are the most commonly available

two broad categories

Stepper motor driven

Most stepper motor-driven robots are of the open loop type.

Feedback loops can be incorporated in stepper-driven robots.

Direct Current (DC) servo-motor driven

Servo-driven robots have feedback loops from the driven components back to the driver.

Pneumatic drive

Generally used for smaller robots

Have fewer axes of movement

Carry out simple pick-and-place material-handling operations, such as picking up an object at one location and placing it at another location

These operations are generally simple and have short cycle times

Here pneumatic power can be used for sliding or rotational joints

Pneumatic robots are less expensive than electric or hydraulic robots

CONTROL SYSTEMS

The Joint movements must be controlled if the robot is to perform as desired

Micro-processor-based controllers are regularly used to perform this control action

Controller is organised in a hierarchical fashion <U:\Private\Industrail Robot\Controller in a hierrchical fashion.png>

Limited Sequence Control

Elementary control type, it is used for simple motion cycles, such as pick and place operations

It is implemented by fixing limits or mechanical stops for each joint and sequencing the movement of joints to accomplish operation

Feedback loops may be used to inform the controller that the action has been performed, so that the programme can move to the next step

No servo-control exists for precise positioning of joint. Many pneumatically driven robots are this type

Playback with Point to Point Control

Playback control uses a controller with memory to record motion sequences in a work cycle, as well as associated locations and other parameters and then plays back the work cycle during programme execution

Point to point control means individual robot positions are recorded in the memory.

These positions include both mechanical stops for each joint and the set of values that represent locations in the range of each joint.

Feedback control is used to confirm that the individual joints achieve the specified locations in the programme

Playback with Continuous Path Control

Continuous path control refers to a control system capable of continuous simultaneous control of two or more axes

Greater storage capacity—the number of locations that can be stored is greater than in point to point and interpolation calculations may be used, especially linear and circular interpolations

Intelligent Control

An intelligent robot is one that exhibits behaviour that makes it seem intelligent

For example, capacities to interact with its ambient surroundings, decision-making capabilities, communication with humans; computational analysis during the work cycle and responsiveness to advanced sensor inputs

They may also possess the playback facilities of the above two instances.

Requires a high level of computer control and an advanced programming language to input the decision-making logic and other ‘intelligence’ into the memory

Each joint can feed back control data individually, with an overarching supervisory controller co-ordinating the combined actuations of the joints according to the sequence of the robot programme.

END EFFECTORS

known as robot hand

It is mounted on the wrist, enables the robot to perform specified tasks

Various types of end-effectors are designed for the same robot to make it

more flexible and versatile

two major types

Grippers

Grippers grasp and manipulate objects during the work cycle

Typically the objects grasped are work parts that need to be loaded or unloaded from one station to another

It may be custom-designed to suit the physical specifications of the work parts they have to grasp

In detail

Mechanical gripper

Two or more fingers that can be actuated by robot controller to open and close on a work part.

Vacuum gripper

Suction cups are used to hold flat objects

Magnetised devices

Making use of the principles of magnetism, these are used for holding ferrous work parts

Adhesive devices

Deploying adhesive substances these hold flexible materials, such as fabric

Simple mechanical devices

hooks and scoops

Dual grippers

Mechanical gripper with two gripping devices in one end effector for machine loading and unloading.

Reduces cycle time per part by gripping two work parts at the same time.

Interchangeable fingers

Mechanical gripper whereby, to accommodate different work part sizes, different fingers may be attached

Sensory feedback fingers

Mechanical gripper with sensory feedback capabilities in the fingers to aid locating the work part and to determine correct grip force to apply (for fragile work parts).

Multiple fingered grippers

Mechanical gripper with the general anatomy of the human hand.

Standard grippers

Mechanical grippers that are commercially available, thus reducing the need to customdesign a gripper for each separate robot application.

Tools

Tools are used to perform processing operations on the work part

robot uses the tool relative to a stationary or slowly moving object.

Application

Spot welding gun

Arc welding tool

• Spray painting gun

• Rotating spindle for drilling, routing, grinding, etc.

• Assembly tool (e.g. automatic screwdriver)

• Heating torch

• Water-jet cutting tool

Sensors

Internal sensors

Internal sensors are used to monitor and control the various joints of the robot

They form a feedback control loop with the robot controller.

Examples of internal sensors include potentiometers and optical encoders, while tachometers of various types can be deployed to control the speed of the robot arm

External sensors

These are external to the robot itself

They are used when we wish to control the operations of the robot with other pieces of equipment in the robotic work cell

External sensors can be relatively simple devices, such as limit switches that determine whether a part has been positioned properly or whether a part is ready to be picked up from an unloading bay

Micro Sensor board <U:\Private\Industrail Robot\micro sensor board.png>

Advanced sensor model <U:\Private\Industrail Robot\Advanced sensor in robot.png>

Tactile sensors

Used to determine whether contact is made between sensor and another object

touch sensors which indicate when contact is made

force sensors which indicate the magnitude of the force with the object.

Proximity sensors

Used to determine how close an object is to the sensor. Also called a range sensor

Optical sensors

Photocells and other photometric devices that are used to detect the presence or absence of objects. Often used in conjunction to proximity sensors

Machine vision

Used in robotics for inspection, parts identification, guidance and other uses

Miscellaneous category

temperature, fluid pressure, fluid flow, electrical voltage, current and other physical properties.

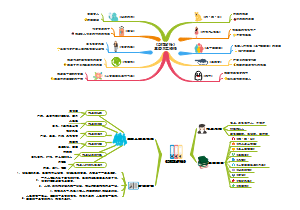

The next robotics

The trends

Long volume high mix

Shorter cycles faster lanches

Increased need for automation and scalability in SMEs

Rising cost of downtime

Increased and sporadic human intervention

The challenges

Automation complexity and unpredictability

Shop floor disruptions and high engineering cost

Lack of robot integration and programming expertise

Higher lifetime TCO due to increase in planed downtime

Lost productivity to maintain safety

The enablers

Collaborative automation for greater flexibility

Better software for engineering efficiency

Easier to use robot with more intuitive programming

Advanced analytics and services for greater reliability

Collaborative automation to maintain safety and productivity

Innovations

Standardisation, Benchmarking and Regulation

Barriers to development, market and use

Lack of knowledge and of concern about standardisation issues (relevant also at the societal level) in the scientific and robotics community at large

Lack of robotics specific political and regulatory drivers

Lack of research and coordination actions to support industry, SMEs and research to include the environmental performance, the LCA, the 3Rs issues in their products, use cases and prototypes.

Lack of coherent theoretical and functional framework of the domains, hence requirements and terminology are not consistent across stakeholders

Large variety of robot architectures with different interaction capabilities

Lack of reusability of the hardware and software modules across research/industrial organizations (lack or interoperability)

Main international robot standardisation issues

Safety standards

Vocabulary standards

Performance standards (safety-related first and then non-safety-related)

Inter-operability (or modularity) standards

candidates for standardisation

Boundaries/classification between different robot domains as well as between robot and non-robot domains

Standardisation of complex robot processes

Human-robot interaction/collaboration standardisation

Environmental impact certification

Keys issues of Standardisation for Robot Domains <Industrial%20robot/Standardisation%20of%20robot%20domains.JPG>

Standardisation areas

Current developments and opportunities

Contributions to key technology readiness levels

Future opportunities and why relevant

Barriers to development

Barriers to use

Relationship to other topics and market domains

Europe’s position in the standardisation process and European contributions

Key stakeholders

standardization in Human Robot Interaction

Standardising robot’s spatial behaviours in response to human presence

Standardising robot’s noise level for robots in human environment

Standardising perception for HRI

Standardising generic and high-priority commands for HRI

Standardising interfaces for HRI with respect to type of service and media

Standardising gestures across different cultures

Main international robot standardisation projects

Ongoing international projects on robot standardisation <Industrial%20robot/Main%20international%20robot%20standardisation%20projects1.JPG>

Ongoing international projects on robot standardisation <Industrial%20robot/Main%20international%20robot%20standardisation%20projects2.JPG>

Relevant robot standards and documents <Industrial%20robot/Relevant%20robot%20standards%20and%20documents.JPG>

Relevant robot standards and documents <Industrial%20robot/Relevant%20robot%20standards%20and%20documents2.JPG>

Key standardisation targets

o

o

Further opportunities

Standard (languages) for describing complex processes (similar to BPMN for business processes)

Classification of complex processes

Setting of quality reference levels (maybe in combination with benchmarking studies or competitions

MAR Technology Readiness Levels (TRLs)

the assignment of a TRL

Technology developments delivered as a module.

Software modules delivered as part of a system.

Systems consisting of multiple integrated technical elements.

Platforms developed for a specific application.

Deployed systems consisting of multiple platforms and support systems

TRL level steps

Level 1 - Basic Principles Observed

Basic technology research

Technical feasibility is assessed, basic principles are laboratory tested, technology requirements established, comparative reviews conducted, similar technology in other areas of use assessed.

Outcome

Technically detailed document which describes a product, application, technical feature or module and indicates the potential market requirement and likely technical requirements. Typically includes a detailed functional description, customer benefit analysis, ideas for realisation, and a detailed technical progression plan

Level 2 - Technology Concept Formulated

Basic technology research

Proof of principle developments including all engineering and systems development (e.g. algorithm development, physical schematics, and simulations). Critical parts of the system are tested in laboratory conditions to show how the technology operates and to provide insights into functional and practical limitations. Assessment of the integration between the proposed components

Outcome:

Bench demonstration of key technical concepts. Concept formulated with details of potential technical and development risks, including estimated resource requirements and test planning. Understanding of the design and engineering parameters and their interrelationships with the desired system parameters and key requirements

Level 3 - Experimental Proof of Concept

Technology development

Key technical elements developed as sub-systems to allow assessment of the core ideas and test practical realisation. Realisation of parts of the concept to assess the product (e.g. computer simualtion models, physical models, assessment of user interaction, consideration of deployment etc.). Bench development of key technical elements, features or modules able to validate the viability of the concept within the application parameters. Benchmark testing of system or module performance and comparative assessment with existing systems

Outcome:

Results and demonstrations that the concept is technically feasible, a first set of modules or components have been develop and tested to show performance compatible with the requirements. Interfaces developed between module and within systems. Detailed future technical scope of work identified

Level 4 – Technology Validated in Laboratory

Laboratory demonstration

Technology is demonstrated in a laboratory or development testing environment where testing parameters are designed to demonstrate the limits of the technology with respect to the requirements. Testing of system or major sub-systems validated against established technical benchmarks relevant to the end user. Testing of internal and external interconnectivity and integration between components in the system. Demonstration and understanding of the impact of the underlying design and engineering parameters on system performance. Initial normative testing with trained users to provide initial usability information

Outcome:

Demonstration that the technology is expected to scale to achieve end user relevant technical requirements or shows sufficiently improved performance, over existing systems, using established benchmarks. Usability testing results providing insight into areas for future development and their prioritisation. Clear plan for integration and identification of technical risks and their potential impact and severity. Documentation of technical development plan

Level 5 – Technology Validated in Relevant Environment

Laboratory Validation

Integrated system developed to perform in an environment that exhibits the main features of the expected operating environment. Performance is sufficient to validate that the technology could scale to achieve useful function in the intended application area. System contains all critical technical elements but not in the desired form factor (shape, size, power consumption etc.). Core functionality of product, feature or module can be demonstrated within system and operational context

Outcomes:

Identification and prioritisation of the major technical and application risks for the realisation of the product, feature or module. Performance characteristics are well understood. Clear evidence is delivered that the different technical components can be integrated into a unified component or system and can perform the intended function

Level 6 – Technology Demonstrated in Relevant Environment

External technology demonstration

Main functions perform sufficiently close to requirements such that technology can be validated in an environment that is equivalent to the operational environment. First field trials can be conducted when supported by developers to gain fine grained insight into the issues of product, feature or module development.

Outcomes:

The main functionality of product, feature or module can be demonstrated in a realistic environment under realistic test conditions. The concept is realised to a degree such that there is good usability and impact data, gathered from developer supported customer trials. System design documentation is complete. Expected development plan is complete including a detailed technical progression

Level 7 – System Prototype Demonstration in Operational Environment

Product prototype.

System performance is close to the end product, feature or module end user requirement. Development of prototypes with final technology sub-systems or close equivalents in a near to complete form factor (size, weight, power consumption etc.). All functionality required in the end system is capable of being demonstrated. Customer verification trials (independent of developer support) carried out.

Outcomes:

Significant reduction in technical risk. Product operation validated in actual end user environments. Product prototypes realised in close to final form and function. Plan developed for manufacture and deployment including full product testing and certification plan.

Level 8 – System Complete and Qualified

Close to market development

Development of production prototypes with final functionality and form factor. System is sufficient for end user testing in limited launch markets over extended periods of operation. Initial batch production of the product using end manufacturing processes for most parts. Product material and functional quality is at production levels. Product certifiable for use in chosen market.

Outcome:

Product validated for manufacture through extended customer trials, failure mode analysis complete. Certification obtained. All production processes validated and process variations assessed and tested. Full materials and part specifications complete. Product test data validated against end user requirements. Manufacturability fully assessed

Level 9 - Actual System Proven in Operational Environment

In production

Set up of production facilities, production test systems completed, volume components sourced.

Outcomes:

Series production and sales

TRL examples <Industrial%20robot/TRL%20examples.JPG>

Few advantages

Robots never get sick or need to rest, so they can work 24 hours a day, 7 days a week

When the task required would be dangerous for a person, they can be do the work instead

Robots do not get bored. So the work that is repetitive and unrewarding is of no problem for a robot

Specific advantages in manufacturing

increased payload capacity

greater accuracy

increased reach and range of motion

improved speed and acceleration

faster communication with external equipment

better safety features and lower operational costs

It can readily be learned by shop personnel

It is a logical way to teach a robot

It does not require knowledge of computer programming

Few disadvantages

Downtime regular production must be interrupted to program the robot

Limited programming logic capability.

Not readily compatible with modern computer based technologies

Robot economics and safety

Economics

Purchase Price of the Robot

Special Tooling

Installation

Maintenance and Periodic Overhaul

Operating Power

Finance

Depreciation

Increased Productivity

Quality Improvement

Increase in Throughput

Safety

Accidents

The arm of a robot suddenly shot up as the oil-pressure source was cut off after the robot ended work.

A robot made a motion that was not part of its program

A robot started moving as soon as its power source was switched on, although its interlock conditions were still not ready

When operating alone, a robot destroyed the work it was to weld because of a mistake in program instruction

During hot summer weather, the arm of a robot sprang up, although it had otherwise been working normally

Reasons for safety

For programming, humans must enter the workspace of robots

Monitoring, tool changing, inspection, and other operations involving robots or their peripheral equipment are still done by humans

To correct problems with peripheral equipment, it is necessary to enter the workspace of robots

Since each robot installation is different, each presents unique application problems

In programmed or accidental halt, the operator might enter the workspace to inspect the work or investigate the trouble

Requirements

the design of a reliable control system to prevent malfunctions

the design of the workstation layout

training of plant personnel (programmers, operators, and maintenance staf

Guidelines

The robot working area should be closed by permanent barriers (e.g., fences, rolls, and chains) to prevent people from entering the area while the robot is workin

Access gates to the closed working area of the robot should be interlocked with the robot control

An illuminated working sign, stating “robot at work,” should be automatically turned on when the robot is switched o

Emergency stop buttons must be provided in easily accessible locations as well as on the robot’s teach box and control console

Pressure-sensitive pads can be put on the floor around the robot that, when stepped on, turn the robot controller off

Emphasise safety practices during robot maintenance

Great care must be taken during programming with the manual reaching mod

The robot’s electrical and hydraulic installation should meet proper standards

Power cables and signal wires must not create hazards if they are accidentally cut during the operation of the robo

If a robot works in cooperation with an operator, the robot must be programmed to extend its arm to the maximum when forwarding the parts so that the worker can stand beyond the reach of the arm

Mechanical stoppers, interlocks, and sensors can be added to limit the robot’s reach envelope when the maximum range is not required

Three levels of sensor system

Perimeter penetration detection around the workstation

Intruder detection within the workstation

Intruder detection very near the robot (a “safety skin”)

End users market domains and robotics can apply

Logistics&transport(The details you can find in papers Robotics 2020)

People transport

Goods transport

Warehousing

Commercial

Mining & minerals

Utilities & services

Construction and demolition

Inspection and monitoring

Markets

Civil

Civil infrastructure

Environment

Search and rescue

Law enforcement

Emergency service

Science support

Consumer

Domestic appliances

Assistive living

Entertainment

Education

Agriculture

Livestock

Forestry

Fisheries

Healthcare

categories

Surgical

Systems that directly extend surgical dexterity and efficacy

Systems that enable remote diagnosis and intervention, both over long distances and in intra-corporeal settings

Systems that assist during diagnostic procedures

Systems that assist during surgical procedures

Therapy and rehabilitation

Functional replacement aids

Neuro-rehabilitation

Prosthetics

Mobility support systems

Training

Assistive robotics

Medium Term Requirements

Leg exoskeletons that adjust behaviour to the individual behaviour and/or properties and optimize their support according to the user or environment

Robots to be used in autonomous rehabilitation (e.g., game-based rehabilitation, upper limb post-stroke rehabilitation) should understand the user needs and reactions and adapt the therapy to them

Robots to assist mobility and manipulation should be able to interface naturally with people and guarantee safety and operability in “natural” environments

Rehabilitation robots designed to promote sensory-motor integration by providing bidirectional communication, including multimodal command input (myoelectric signals, inertial sensing) and multimodal feedback (e.g., electro-tactile, vibro-tactile and/or visual)

Arm/wrist/hand prostheses which automatically adapt to the patient, enjoying single fingers flexion/extension, thumb rotation, wrist DOFs

Prostheses and rehabilitation robots enhanced with semi-autonomous control to improve performance and/or decrease the cognitive burden to the user

Prostheses and rehabilitation robots that exploit vast online resources (information, storage, processing power) through Cloud Computing to implement advanced functions that are far beyond the capabilities of the on-board electronics and/or direct user control

Low-cost prosthetics and robotics designed through new additive or generative manufacturing methods (3D printing)

An at-home therapy relieving the intensity of neuropathic pain or phantom limb pain by means of advanced interpretation of the residual muscle signals, and with the aid of a robotic hand (less dexterity needed than in the previous case) and/or a VR environment.

Biomimetic control for physical surgeon robot interaction

Adequate mechanical actuation and sensing technologies for the design of dexterous force-feedback miniature robots and instruments for advanced and enlarged Miniinvasive surgery application.

Power harvesting for implantable micro-robots

integration of volitional residual subject motion, eventually supported by FES to enhance motor relearning, with robot control

Development of clinically applicable methods for movement restoration that reach beyond the commonly used state-machine, manually-tuned paradigms

Systems Development

Assistive and Rehabilitation

Definition of standards allowing enhanced interoperability of multimodal components including haptic force and tactile components and plug and play interfaces

Standardised system architecture, also including interfaces with home electronics, health care / hospital IT infrastructure and AAL systems

Surgery

Real-time OS and dedicated surgical robotic middleware

Plug and play interoperable surgical robotic standardized middleware

Workflow and ontology based procedure guidance and control

Architecture for linking real-time image processing and reconstruction to robotic middleware

Medically certified real-time OS and robotic middleware

Systems Integration

Surgery

Fully integrated force/tactile feedback devices, self-sensing

Medically certified sensors, hardware components and software libraries for composing of new (procedure-specific) surgical robots and devices

Vision-integrated surgical robot control, stereo-displays

Standardized surgical cockpit for multiple disciplines

Rehabilitation

Systems combining force and tactile feedback

Wearable systems with open interfaces for establishing collaborative body area networks, including assistive systems (e.g., prostheses) and other general-purpose sensing and communication devices (e.g., smartphones, smartwatches).

Modelling and Knowledge Engineering

Assistive

Extension of object modelling through computer vision through other forms of sensing (infrared, tactile)

Database of typical motion and interaction patterns during care processes, format should allow care personnel to verify correctness of learnt models

From ontological learning to phylogenetic and social learning. Formal methods for knowledge integration also on a collaborative way with other robots (internet of things for problem solving)

Models for safety verification, specifically taking into account (all) possible environment structures, human postures and motion etc. the robot could come into contact with

Modelling of specific care processes that should be supported by the robot (carer interacting with environment and patient)

Surgery

Surgical knowledge database and means for retrieval of relevant context-dependent knowledge for online feedback and guidance (suggesting optimal procedure or intervention approaches).

Ontology to structure the knowledge of surgical procedures

Use of atomic surgical steps and their composition to generate patient specific intervention plans

Rules for robotic surgery planning Interaction of learning and modelling paradigms

Real-time FEM soft tissue modelling,

Modelling of tissue damage for damage detection and prevention

Online reconstruction of anatomic structures

Modelling of intervention on tissue, muscles, organs

Modelling of physiological and biological functions

Intra operative tissue deformation modelling

Compliant robots modelling, flexible robot-tissue interaction modelling

Online identification of human motor control

Task and surgical workflow modelling

Flexible robots-tissues interaction modelling

Task and surgical workflow modelling

Rehabilitation

Better models of human motor control

Guidance cues through overlay technology, library with expert procedure execution samples

Semi-autonomous prosthetic reaching, grasping and manipulation

Interfaces for exploiting the vast knowledge resources that are available online (object model repositories and know-how instructions)

Afferent/natural feedback in prosthetics

Assistive

Standardized methods such as Wizard-of-OZ to verify target functionality with end users before starting new hardware and software developments

Use of existing research platforms to verify functionality before building dedicated assistive device

Design concept to adjust robot hardware and functionality to individual user requirements

Methods to create functional robot design, i.e. visual appearance that mirrors the robot’s abilities

Surgery

Specific design methodologies for sterilise-able and safe surgical robots

Intra-corporeal robotic system design methods

Multimodal VR training platforms design and validation methods

Public databases of surgical procedures (images, forces, physiological parameters and other data sources) for requirement distillation.

Guidelines, equipment and algorithms for setting up a Smart OR that gathers all relevant data for requirement distillation or validation.

Principled methods for analysis of the workspace, surgical workflow, surgical tasks and surgical skill for requirement distillation.

Reproducible artificial mock-ups that replicate the behaviour of the relevant properties of real organs or body parts for use in requirement distillation, benchmarking and validation

Manufacturing

Categories

Production

Electronics assembly

Automotive parts manufacture and automotive assembly

General production of metal, rubber or plastic parts.

Food processing

Food

SME manufacturing

The need to design systems that are cost effective at lower lot sizes.

The need to design systems that are intuitive to use and are easily adapted to changes in task without the need to use skilled systems configuration personnel.

The ability to work safely in close physical collaboration with human operators

robotics can apply

lean and agile manufacturing,

miniaturised assembly,

introduction of Cyber-physical production systems (CPS) for example the “Industrie 4.0” programme in Germany,

introduction of intuitive and adaptive manufacturing systems including intuitive programming and tasking,

deployment of Dual-arm, lightweight, low-cost compliant manipulators,

increased cooperation with humans including physical cooperation,

novel business models and deployment strategies.

Barriers to Market

User awareness of robotics technology capabilities

User concerns about system complexity

Cost of ownership and return on investment

Flexibility and adaptation of systems to changing needs

Key Technology Targets

intuitive handling,

easy to use,

easy to (re-)configure,

adaptable,

provide safe perception and safe actuation with certified components and systems,

provide an ergonomic design for human interaction

are energy efficiency, provide energy autonomy and short charging cycles

provide privacy for personal data gathered during human interaction

Systems Development

Modelling and Knowledge Engineering

Mid term

Standard software for modelling environment / robot cell / robot line, including sensors and actuated components.

Physics engine for real time information on physical quantities in robot application.

Long term

Multi physics enabled model of robot application, including all relevant effects (e.g. sol id, fluid, electrical, magnetic, thermal, etc.)

Real time availability of all relevant physical information on environment and application, to be used as a basis for real time adaptive motion planning, prediction and control

Domain specific ontologies for application description

Mechatronics

Mechanical Systems

Appropriate design for physical interaction, design principles for safe interaction

Zero cable robot

H igh performance robot based on low cost / low accuracy components

Appropriate design of drive components and kinematic structures for physical interaction, design principles for safe interaction

Actuators

Low cost, modular drive systems with integrated sensing (e.g., position, torques)

Low power consuming drives and control methodologies

Multi fingered industrially proven robust grippers

Safe components (SIL / performance level D)

Light weight, intelligent structures (with sensors integrated)

Lightweigh t actuation principles, high power density, low friction gears with high transmission ratio

Direct drives for high loads

Sensors

New safety rated sensors for Physical Human Robot Interaction (e.g. Capable of returning positions of objects / operators in sc ene)

Sensor redundancy for safety rated applications, e.g. Information fusion from diverse sensing types

General 3D Work/Object scan and monitoring for real time path correction

Use of information available in the area from distributed sensors, e.g. to tre at occlusions and lift perspective redundancy of 3D perception

Control

New control paradigms with constraint based optimisation and use of task redundancy for best trade off among different objectives (e.g. productivity, manipulability, safety, ergonomics.

Sensor based control with adaptation to unforeseen situations (e.g. obstacles, humans...)

Online control based dynamic path re planning (e.g. from sensor information)

Safety

Methods and tools to adapt robot motion to injury risk knowledge (see TG pHRI)

Intelligence and decision-making capability for autonomously generating dynamic safety zones based on live robot movements (as opposed to pre-programmed motions

Perception

Interpretation

Combination of various sensing technologies to achieve safety-rating of the information

Integrate new sensing capabilities into existing systems as safety-rated systems

Sensing

Use sensor information redundancy to detect faulty situations (e.g. sensor failures, control failures, etc.)

Combination of various sensing technologies to achieve safety-rating of the information

Bringing new sensing capabilities into routine industrial use as safety-rated systems

Self-calibrating safety sensors

Navigation

Localisation

Task appropriate indoor positioning in industrial environment, e.g. combination of platform + manipulator

Motion Planning

Capability to autonomously generate alternate motions to avoid collisions (safety rated algorithms)

Autonomous path planning with obstacle avoidance in cluttered environments

Reactive motion planning, i.e. online planning revision, based on current sensor information

Cognition

Learning Development and Adaptation

Learning Affordances for Robot Object Interaction.

Task learning by demonstration, human-robot and robot-robot interaction

Natural Interaction

Passive and Active Safety of Mobile Manipulation in Human Workspace

Ergonomic Evaluation, Analysis of Workspace Sharing Systems

Instruction and Assistance in Semi-Automated Assembly Processes

Intelligence and decision-making capability for autonomously generating dynamic safety zones based on live robot movements (as opposed to pre-programmed motions)

System abilities

Adaptability

Parameter

Component

Task

Configurability

Dependability

Failure

Functional

Environment

Interaction

Interaction Ability

Human robot

Robot robot

Human robot interaction safety

Social interaction duration

Social interaction range

Social interaction role

Perception Ability

Tracking

Recognition

Scene

Location

Cognitive ability

Action

Interpretive

Envisioning

Learning

Reasoning

Decisional Autonomy

Manipulation Ability

Grasping

Holding

Handling

Motion A bility

Constrained

Unconstrained