导图社区 5. Etching

- 19

- 0

- 0

- 举报

5. Etching

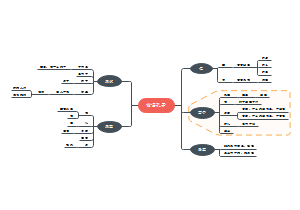

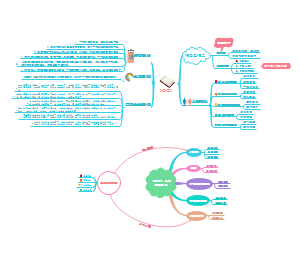

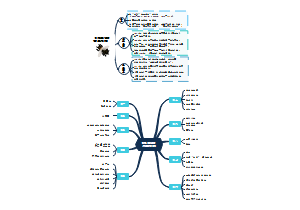

这是一篇关于5. Etching的思维导图,主要内容包括:Considerations for Dry Etching,Etch Rate Dependence,Dry Plasma Etching,Wet Chemical Etching,requirements and tradeoffs。

编辑于2024-10-07 12:03:16- 制造技术

- Etching

- 5. Etching

这是一篇关于5. Etching的思维导图,主要内容包括:Considerations for Dry Etching,Etch Rate Dependence,Dry Plasma Etching,Wet Chemical Etching,requirements and tradeoffs。

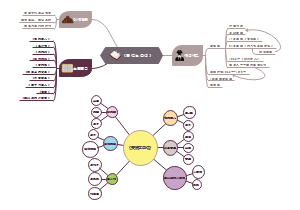

- 1. Introduction and Overview of nanotechnology

这是一篇关于1. Introduction and Overview o的思维导图,主要内容包括:Applications of Nanotechnology to Devices and Microsystems,Scaling Devices to Nanometer Range,Why Nanotechnology for Advanced Microelectronics and Bi

5. Etching

社区模板帮助中心,点此进入>>

- 5. Etching

这是一篇关于5. Etching的思维导图,主要内容包括:Considerations for Dry Etching,Etch Rate Dependence,Dry Plasma Etching,Wet Chemical Etching,requirements and tradeoffs。

- 1. Introduction and Overview of nanotechnology

这是一篇关于1. Introduction and Overview o的思维导图,主要内容包括:Applications of Nanotechnology to Devices and Microsystems,Scaling Devices to Nanometer Range,Why Nanotechnology for Advanced Microelectronics and Bi

- 相似推荐

- 大纲

5. Etching

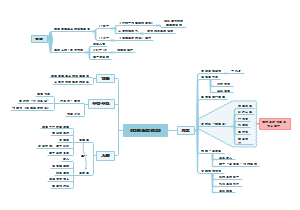

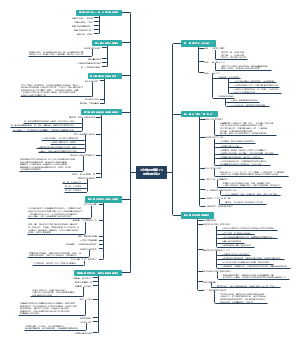

requirements and tradeoffs

lithography-pattern etch mask(图案刻蚀掩膜);Etching- selectively remove materials to form functional devices

requirements

Flexibility to Optimize Processes

Low Cost and High Throughput System With Low Downtime

Uniform Etching Better Than 5%

Minimize Etch Rate Dependence on Feature Size, Wafer Size, Etch Depth, Aspect Ratio, Adjacent Features, Position on Wafer

High Selectivity to Mask and Layer Below

Good Profile Control to Avoid Undercutting

Low Device Damage With Low Ion Energy and Uniform Plasma

Low Particle Generation

Environmental Issues to Reduce Chemical Waste(化学废物)

etching classification

wet etching

dry etching

etching profile

isotropic

Same Etch Rates in Vertical and Horizontal Directions, Undercut(削弱) with Lateral Etching(横向刻蚀) under Etch Mask

anisotropic

completely anisotropic

Completely Anisotropic – No Lateral Etching, only Etch in Vertical Direction with Vertical Profile, Preferred for Small Features

etch selectivity

Etch Rate Ratio between Material to be Etched and Etch Mask

Etch Mask Holds up with High Etch Selectivity

Not Etching Layer Underneath

Wet Chemical Etching

Usually for Surface Cleaning and Complete Removal of a Layer (e.g. Photoresist, Oxide)

Advantages

Low Cost, Simple System

Highly Selective to Mask and Underlying Layer

Batch Processing(批处理) With Larger Number of Wafers (>24) at a Time for High Throughput

Disadvantages

Isotropic Etch With Undercut Profile(削弱轮廓)

For Small and High Aspect Ratio Features, Difficult to Get Solvents in and Out, Can Cause Non-Uniform Etch

Need to Provide Waste Treatment for Large Quantity of Solvents

isotropic ethcing

similar etch rates in the vertical and horizontal directions

Features Become Larger with Rounded Profile After Etching

Difficult to Control Exact Dimension or Profile

Surface Roughness Developed due to Preferential Etching

Solutions

Anisotropic Wet Etching

Faster Etch Rate in One Direction than the Other

Etch Stop or Selectivity based on Doping(参杂)

Etch Rate Depends on Crystalline Structure(晶体结构)

Dense Crystal Planes(<111> in Si, Etch Slower than Less Dense Planes (<100> or <110>))

Anisotropic Si Etching

(111) Si Planes have the Highest Atomic Density compared to (100) or (110) Planes

Etch Rates (110) : (100) : (111) = 600:400:1

Vertical Profile on (110) Si

Tapered Profile(锥形) with 54.74° on (100) Si (V-Groove)

When 2 <111> Planes Meet, Etching Stops

Minimum Opening Size Needed to be able to Etch Through given Thickness

Able to form Devices with Sharp Pointed Tips (e.g. Field Emission Tips) and Openings with Tapered Sidewalls(锥形侧壁)

Comparisons

KOH

Common Solution, Easy Disposal; Orientation Dependent Etch, Smooth Surface; Mobil Ion (K+) Contamination

Alkali Metals(碱金属): Contamination for Integrated Circuits

Highly Selectivity

Etch Stop – Boron Doped(硼参杂) >2X10^19 cm-3

Typical Mixture

EDP

Selective Etch with p++ Etch Stop; Metal Etch Mask (e.g. Cr, Cu, Ta, ...) Except Al; dangerous, Reflux Condenser (回流冷凝)Needed

TMAH

No Mobile Ion, Safer, Easier to Setup; Al as Etch Mask with Si Added or Lower pH; Rougher Surface

Maximum Etch Depth Depends on Feature Size

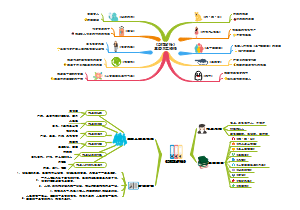

Dry Plasma Etching

overview

Plasma – Reactive Neutrals (Chemical) and Ions (Physical)

Control Reactions with Materials to be Etched to get Vertical Profile

Plasma Generation

Gas Ionized by external energy (Rf/Microwave Power)

Contains Ions (Positive And Negative), Neutrals, Electrons, Photons

Only 0.1-10 % of the Gas is Ionized

Still mostly Gas Molecules

Reactive Species(反应物质) Generated by Impact Ionization(碰撞电离), Dissociation(解离), Excitation, Relaxation, and Recombination

Electron Impact(轰击) Ionization-Remove Electrons from Atom/Molecule (Ions can be Directional)

Ionization Potential (Minimum Energy to Remove Most Weakly Bound Electrons) for Ar = 15.8 eV; Multiplication of Electrons Maintains Plasma and Keeps the Processes Going

Excitation - Electrons Jump to a Higher Energy Level within an Atom

Excitation potential (lower than ionization Potential, Easier to Excite within Same Atom) for Ar = 11.56 eV

Relaxation - Unstable Excited State Returns to Ground State by Emission of Photons of Energy Equal to ▲E

Color in Plasma Depends on Characteristics of Atoms/Molecules.

Optical Emission Spectrum: Consists of Excited Etch and product species. Can be Used to Monitor Reactive Species in Plasma and Etch Products

Photon Energy – Identify Species

Light Intensity – Concentration of Species

wavelength

Recombination - Electrons and Ions Recombine to Form Neutral Species, Makes Stable Plasma with Fixed Number of Electrons and Ions. Otherwise Electron and Ion Density will Keep Increasing

Dissociation - Break Apart Molecules

Electron Attachment: Generate Reactive Ions

Ion-Neutral Collisions: Charge Transfer(电子转移) or Further Ionization, Change Energy Distribution of Ions and Neutrals in Reactor

Voltage Distribution Across Electrodes

High Density Plasma Systems (e.g. Inductively Coupled Plasma Source or ICP) Can Be Used to Reduce Vdc and Increase Concentration(浓度) of Reactive Species

More Flexible – Separate Power Supplies for Source (Reactive Species Concentration) and Stage (Reactive Ion Energy)

High Ion Density, Lower |Vdc|

Barrel Etcher

Minimum Ion Bombardment, Isotropic Dry Etch

Use mainly for Removal of Photoresist using O2 Plasma

faster: because of light weight of electrons

Controllable Parameters

Gases - Flow, Mixture

Pressure - Residence Time(停留时间)

Power - Power Coupled In; Frequency; Pulsing

Cycling - Switching Gases, Power, Pressure

Temperature - Activation Energy(活化能), Adsorption, Desorption

Chamber Materials And Conditions

Uncontrollable Parameters

Sample Variation-Material, Mask, Oxide, Residue

Residual Gases - Leak(泄露), Adsorption on Wall, Gases From Previous Cycles

Stabilization – Gas Flow, Pressure, Power

Power Loss - Inefficient Coupling

Wafer Temperature Variation - Poor Thermal Conductance

Meter Offset(仪表偏移) - Recalibration(重新校准) Needed

Pump Speed Variation - Oil and Filter Replacement

Reactions on Wafer Surface

Transport of Reactive Species and Etch Products

Surface Reactions

Physical, Chemical, Ion Assisted; Bottom Surface vs. Sidewall; Etching vs. Deposition(沉积)

Radiation Effects

Charging Related to Plasma Uniformity and High-Density Charged Particles

Defect Generation due to High Energy Photons

Mechanisms

Sputter Etching(溅射刻蚀)

Lower Pressure/Less Chemicals; More Directional, Less Selective, More Damage

Ion-Assisted Etching (Both Physical and Chemical)

Both Physical and Chemical Etching

Chemical Plasma Etching (No Physical)

Higher Pressure/More Chemicals, Less Directional, More Selective, Less Damage

Three Principal Mechanisms

Chemical Etching (Isotropic, Selective)

Etching done by Reactive Neutral Species, such as “free radicals”(自由基)

Additives(添加剂) like O2 can be used which react with CF3 and reduce CF3 + F recombination

More Reactive Species

Higher Etch Rate (More F, Less CF3)

purely Chemical, so isotropic and selective, like wet etching with Undercut Profile

Physical Etching (Anisotropic, Less Selective)

Ion Etching is much More Directional to Form Vertical Profile(electric field)

Etching Species are Ions like CF3+ or Ar+ which Remove Material by Sputtering

Not Selective since All Materials Sputter at about the Same Rate

Physical Sputtering can Cause Damage to Materials, depending on Ion Energy

Faceting(刻面)

Preferential, Faster Etching at Certain Angles (Ion Incidence and Material Removal)

Facets Form at having Angles with Fastest Etch Rate

Faceting can be used to Form Sharp Tips

Trenching due to Enhanced Ion Flux related to Ion Scattering

Redeposition on Sidewalls can be reduced by Stage Rotation

Chemical Reactions Increase Etch Rate

Simplest Case: No Ions Needed (No Plasma)

(High pressure, Chemical only)

Fast

No Ion Damage

Isotropic

Highly Selective

CMOS Compatible

Ion-assisted Etching (Anisotropic, Selective)

Presence of Ions and Reactive Neutrals

Etch Rate Enhancement due to Ions and Reactive Neutrals is Substantial, not just two added together

Anisotropic and High Etch Selectivity

Ion-Assisted Etching with Both Reactive Ions (F+) and Reactive Neutrals (F)

Effects of Gas Chemistry

Formation of Volatile Etch Products(挥发性) (Solid to Gases)

Addition of Inert(惰性) Gases (e.g. Ar, He)

Changes Electron Distribution and Composition of Reactive Species

Dilution(稀释); Stabilization; Cooling; Sputtering

Enhance Reactive Species Generation

Etch Rate Increases due to High [F] and Less Polymer Deposition

Enhance Polymer Formation

Etch Rate Decreases due to More Polymer Deposition and Less [F]

F vs. Cl for Metal Etching

F – Etch Products with Lower Boiling Point are Easier to Remove with Faster Etch Rate and Perhaps More Undercut(底切)

Presence of Ions can Enhance Etch Product Removal

Ion Energy Reduces at High Pressure

Higher Pressure – Lower Ion Energy due to More Collisions

low pressure hel etching product remove

Ions and Reactive Neutrals do not Increase with Pressure due to Recombination

Affect Distribution of Reactive Species, Adsorption(吸附), Desorption

Etch Rate

Etch Rate Decreases as Aspect Ratio(纵横比) Becomes Higher

Limited by Transport of Reactive Species and Etch Products

Comparisons of Si Dry Etching Using F- and Cl-based Gases

Cycling between Etching and Passivation(钝化)

Using F-based Gases

Repeated Many Cycles; Deep Etching with Good Profile; Sidewall Roughness

Scalloping(扇形)

Vertical Striations(条纹)

Insufficient Passivation

Vary with Aspect Ratio

Advantages

Fast Etch Rate

High Selectivity

Flexible Profile Control

Disadvantages

Surface Roughness

Sensitive Process that Requires Precise Balance Between Etching and Passivation

Etch Rate and Profile vary with Etch Depth and Feature Size

Frequent Switching of Instruments

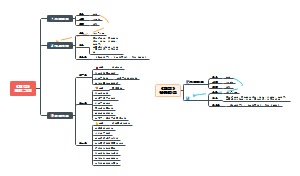

Etch Rate Dependence

Sputtering

Physical Bombardment by Ions only, No Chemical Reaction, Simplest Dry Etching

Sputtering Kinetics(动力学)

Energy Transfer between Incoming Ions (mi, vi) and Target Atoms (mt, vt) through Series of Collisions

Sputtering Yield (S) - Number of Target Atoms Ejected(射出的) Per Incident Ion.

S Depends on Ion Energy, Atomic Mass(原子质量) of Incoming Ion and Target Atoms, Surface Binding Energy(表面结合能) of Target, and Angle of Ion Incidence. High S will Provide High Etch Rate

Eth = Threshold Energy(阈值能量) (~10-50 eV) – Minimum Energy for Etching

Sputtering Yield (S) Increases with mi and Eion

Etch Efficiency

S also depends on angle of incident ions

Ejection of Target Atoms in Forward Direction is Easier with Less Directional Change of Momentum

Off Normal Incidence Confine Action to Surface rather than Deep in Substrate

When θi is too Large (e.g. // to surface), not Sufficient Energy/Momentum Transfer. The Ions just Slide // to Surface at Glazing Angle

Maximum etch rate occurs ~45°, not at normal incident 90°

Etch Rate

Ion Assisted Etching

Considerations for Dry Etching

Deposition During Etching

Charging

Undercut due to Neutrals and Ion Scattering

Mask Erosion

Trenching

Dry Etch Induced Damage

Etching Summary

Precise Control in Feature Size, Etch Depth, Etch Profile, and Uniformity

Low Damage and Minimum Electrical Degradation(电气退化)

High Throughput

Trade-Offs among Multiple Factors

High-Density Dry Etching Systems with Independent Control of Ion Density and Ion Energy (Both Chemical and Physical Etching)

Cycling between Etching and Deposition to Maintain Fast Etch Rate with Vertical Profile

Depends on Lithography and Film Properties

Endpoint-Detection

Etch Should Proceed to End-Point But Not Beyond - Selectivity

Timed-Etch: Inaccurate

End-Point Detection

Optical-Reflection

Emission-Spectroscopy(发射光谱法)

Temperature Controlled Stage

Wafers Pulled-Flat to Chuck(卡盘)

Better Cooling-Efficiency

Less Particle-Generation

Wet vs. Dry Etching

Chemical Consumption and Disposal: liquid vs. gas

Profile Control

Directional Reactive Species(定向反应物) for Vertical Profile

Tapered, Rounded, Mirrors, Lenses

Chemical vs. Physical

Directionality and Density of Neutral Species vs. Charged Particles

Damage

Charging, Ion Bombardment(离子轰击), Contamination