导图社区 钎焊工艺

- 94

- 0

- 0

- 举报

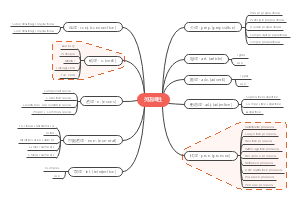

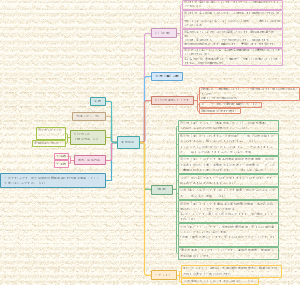

钎焊工艺

这是一篇关于钎焊工艺的思维导图,介绍了焊接过程中的加热速率、钎焊温度、钎焊时间以及冷却速率等关键参数。还提到了钎焊过程在受控环境中进行,以确保焊缝表面的高质量。特别指出了液态填充物的高表面张力,这有助于形成良好的焊缝。主要概述了一个详细的钎焊工艺流程,包括接头设计、材料准备、焊接参数、环境控制以及设备使用等方面。

编辑于2024-06-09 11:24:49- 焊接工艺

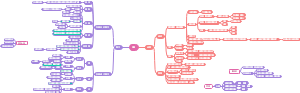

- 钎焊

- 硬钎焊

- 软钎焊

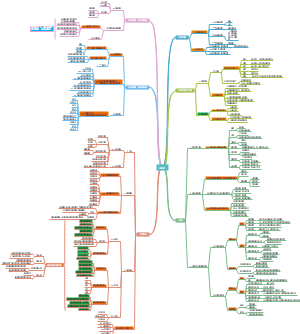

- 汽车行业特殊特性控制方法

汽车行业特殊特性控制方法和手段,详述了多个关键的检测和控制步骤。这包括100%在线检测、过程参数监控(如SPC、注塑温度、焊接电流等)、非破坏性检测、检具批次抽检以及形位公差的检查。在产品分析要求部分,流程聚焦于对比样件100%的目测检测,旨在确保产品的性能、外观、颜色、光泽度等关键特性符合预设标准。这包括对连续性特性(如颜色、光泽度)和离散性特性(如表面质量、皮纹)的严格检查。通过使用色差仪、光泽仪等工具进行数据趋势图监控,流程能够更有效地监控和控制产品的关键特性。

- 汽车行业ABCD零件产品成熟度定义

汽车行业零件产品成熟度是一个综合性的评估指标,它涵盖了产品设计、开发、生产等多个方面。通过成熟度评估,企业可以更好地掌握产品开发进程,确保产品的质量和性能符合市场需求。同时,成熟度评估还有助于企业提高生产效率、降低生产成本,增强市场竞争力。

- 表面工程

详细介绍了有关所有表面处理技术的分类,列出了多种表面处理技术,包括渗金属(如Al、Cr)、渗非金属(如N、C、B)、阳极氧化、表面改性技术、化学氧化、化学转化膜、磷化、转化膜技术、钝化、电化学转化膜等。这些技术根据不同的材料和需求进行选择和应用。还描述了表面处理的多种工艺方法,如感应淬火、表面淬火处理、激光淬火、火焰淬火等,这些方法用于改变材料的表面硬度和耐磨性。

钎焊工艺

社区模板帮助中心,点此进入>>

- 汽车行业特殊特性控制方法

汽车行业特殊特性控制方法和手段,详述了多个关键的检测和控制步骤。这包括100%在线检测、过程参数监控(如SPC、注塑温度、焊接电流等)、非破坏性检测、检具批次抽检以及形位公差的检查。在产品分析要求部分,流程聚焦于对比样件100%的目测检测,旨在确保产品的性能、外观、颜色、光泽度等关键特性符合预设标准。这包括对连续性特性(如颜色、光泽度)和离散性特性(如表面质量、皮纹)的严格检查。通过使用色差仪、光泽仪等工具进行数据趋势图监控,流程能够更有效地监控和控制产品的关键特性。

- 汽车行业ABCD零件产品成熟度定义

汽车行业零件产品成熟度是一个综合性的评估指标,它涵盖了产品设计、开发、生产等多个方面。通过成熟度评估,企业可以更好地掌握产品开发进程,确保产品的质量和性能符合市场需求。同时,成熟度评估还有助于企业提高生产效率、降低生产成本,增强市场竞争力。

- 表面工程

详细介绍了有关所有表面处理技术的分类,列出了多种表面处理技术,包括渗金属(如Al、Cr)、渗非金属(如N、C、B)、阳极氧化、表面改性技术、化学氧化、化学转化膜、磷化、转化膜技术、钝化、电化学转化膜等。这些技术根据不同的材料和需求进行选择和应用。还描述了表面处理的多种工艺方法,如感应淬火、表面淬火处理、激光淬火、火焰淬火等,这些方法用于改变材料的表面硬度和耐磨性。

- 相似推荐

- 大纲

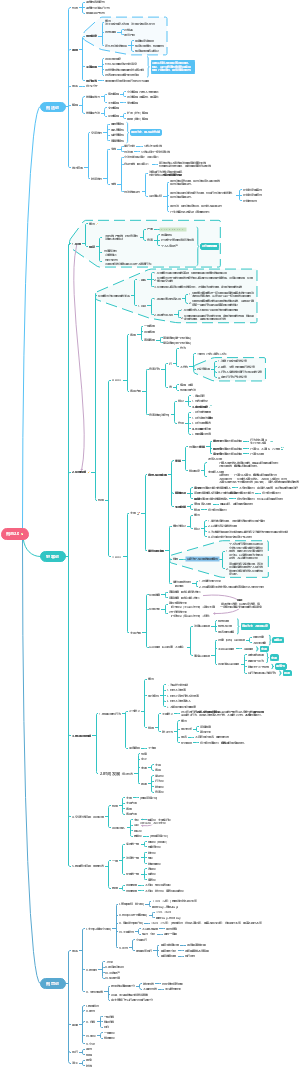

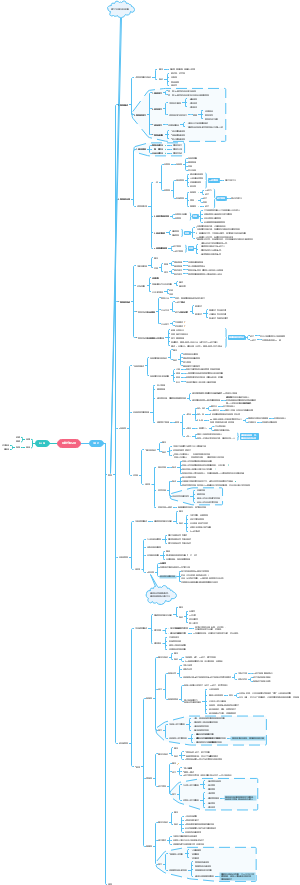

Furnace Brazing Process

1. Basic introduction

Key Focus

Joint design

Material to be joined

Filler metal/钎料

Flux/钎剂

Heating methods

Joint preparation

2. Brazing Process

Process control parameter

Cleaned parts and brazing filler metal are assembled

Heating rate

Brazing temperature

Brazing Time

Cooling Rate

Carried out in a controlled atmosphere

Inert

Vacuum

Appraisal element

Filler metal flow

High surface tension of liquid filler metal

Low contact angle

Low viscosity

Base metal characteristics

Filler metal characteristics

Surface preparation

Joint design and clearance

Temperature and time

Rate and source of heating

Protection by an atmosphere of flux

3. Furnace & Control Instrumentation

High-temperature nickel-base alloys brazing

1095 ℃

Uniformity: ±8℃

Aluminum alloys

Uniformity: ±3℃

Thus it is vital that each work load be closely monitored with a minimum of two thermocouples attached to or embedded in the parts to be brazed.

An alarm system can be installed in the microprocessor to detect any operational abnormality that has the potential to terminate the brazing operation.

Furnace type

Continuous

Semi-continuous

Batch

An alarm system can be installed in the microprocessor to detect any operational abnormality that has the potential to terminate the brazing operation.

4. Advantage

Variables easily controlled to ensure the reliability, brazing atmosphere can be easily regulated

When brazing procedures established, relatively unskilled operators can carry out;

The absence of flux entrapment allows more flexibility in joint design. The postbraze cleaning of the brazed part and the furnace are unnecessary;

Because a whole assembly is heated, distortion of the part can be minimized or eliminated. In some cases, heat treatment of the part can be incorporated into the brazing cycle.

More than one joint per work piece can be brazed in a brazing cycle. Several different assemblies requiring the same brazing conditions can also be brazed simultaneously.

5. Process limitations

Initial investment is relatively high and equipment maintenance is also critical; The cost of a special atmosphere must also be considered.

Because the whole assembly is heated, the cost of heating exceeds that of other brazing operations. In addition, microstructural changes in the base metal can be occured, depending on the material being brazed and the brazing temperature.

Because brazing is performed inside the furnace, joint design is important. The fixtures for holding a brazed assembly require extral heat mass, which increase the manufacturing cost. Proper joint design can minimize or even eliminate fixture complexity.